注射器筒体注塑模具设计【优秀一模二十腔课程毕业设计含creo4.0三维3D建模及17张CAD图纸+带外文翻译+25页加正文0.7万字】-zsmj02

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

3D.stp

Optimization of conformal cooling channels with array of baffles for plastic injection mold.docx

proe creo4

zongzhuangpeiti_asm.stp

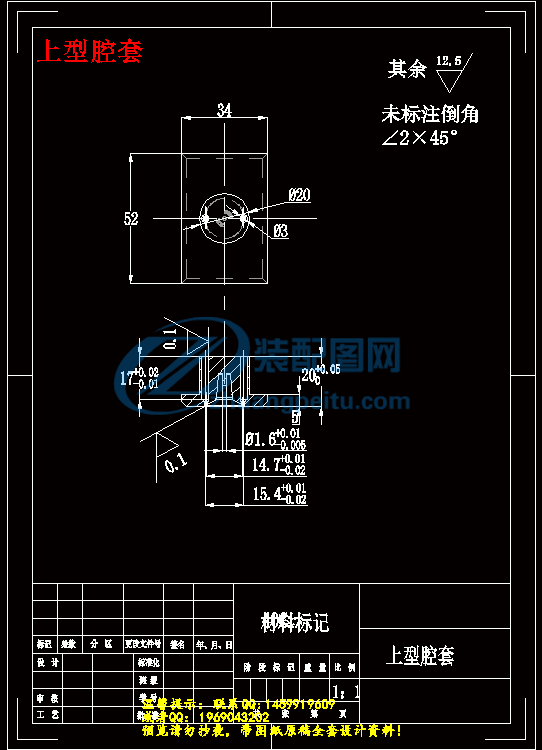

上型腔套.dwg

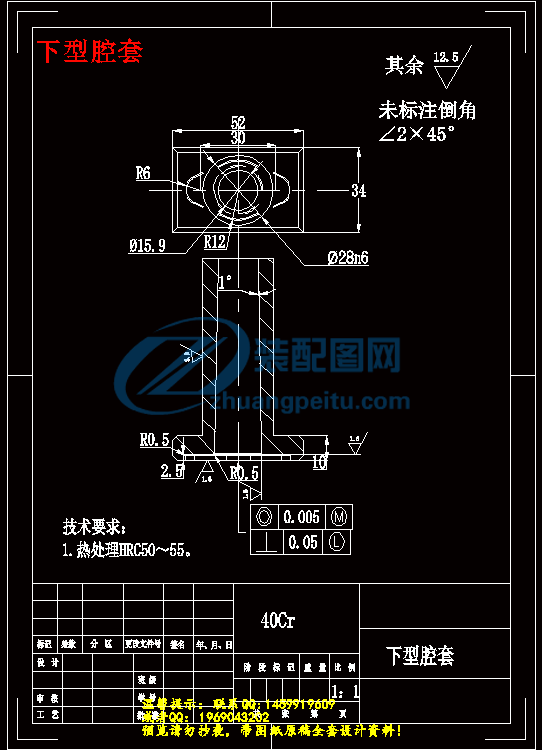

下型腔套.dwg

主浇口.dwg

刮料板.dwg

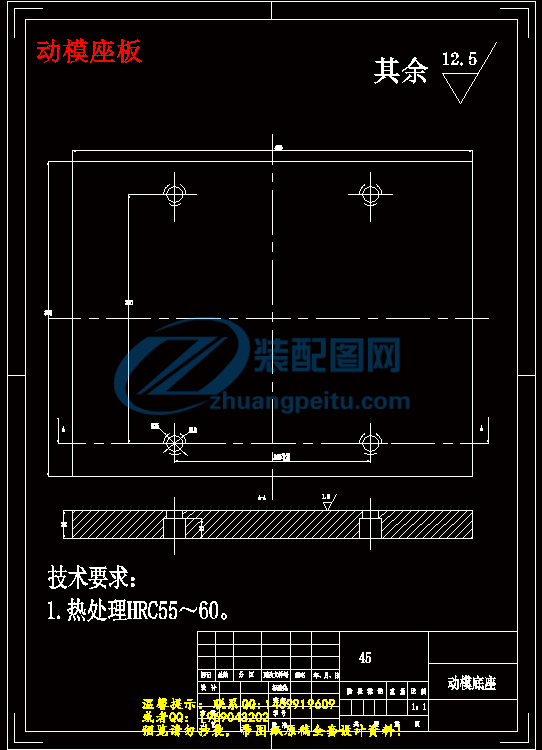

动模座板.dwg

动模板.dwg

图纸总汇.dwg

型腔板.dwg

型芯.dwg

定位圈.dwg

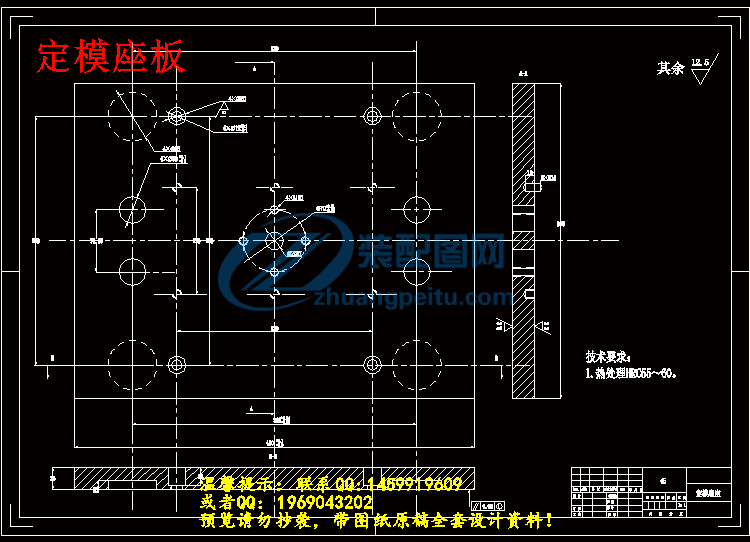

定模座板.dwg

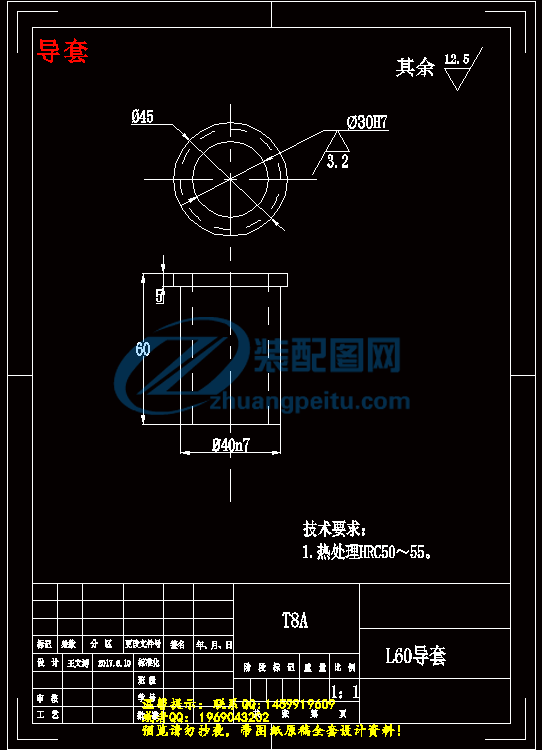

导套.dwg

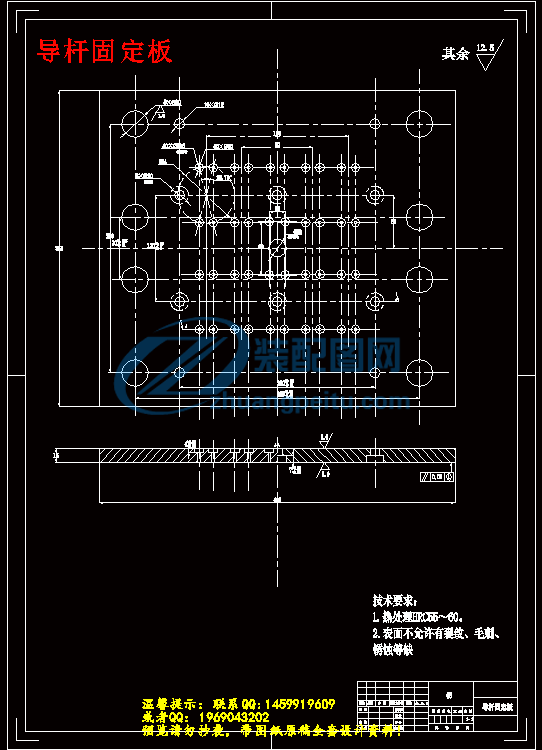

导杆固定板.dwg

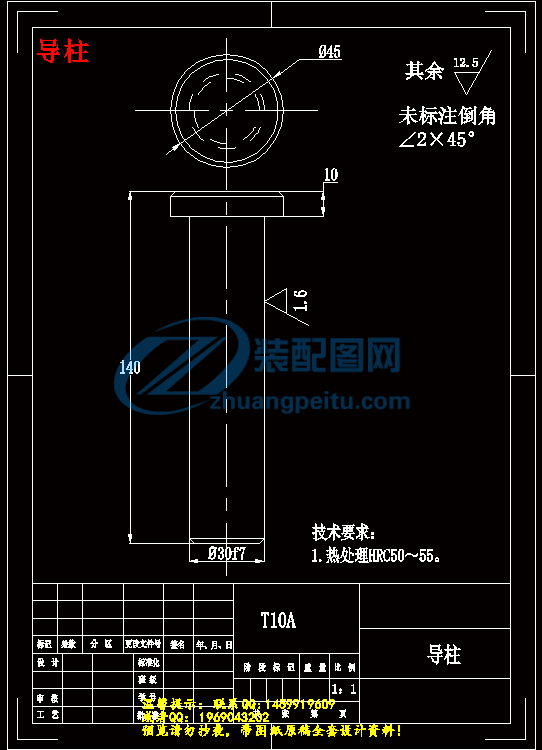

导柱.dwg

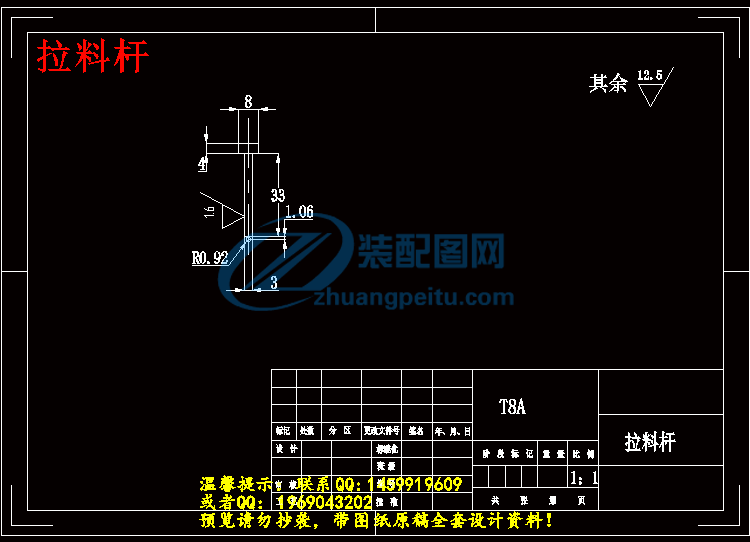

拉料杆.dwg

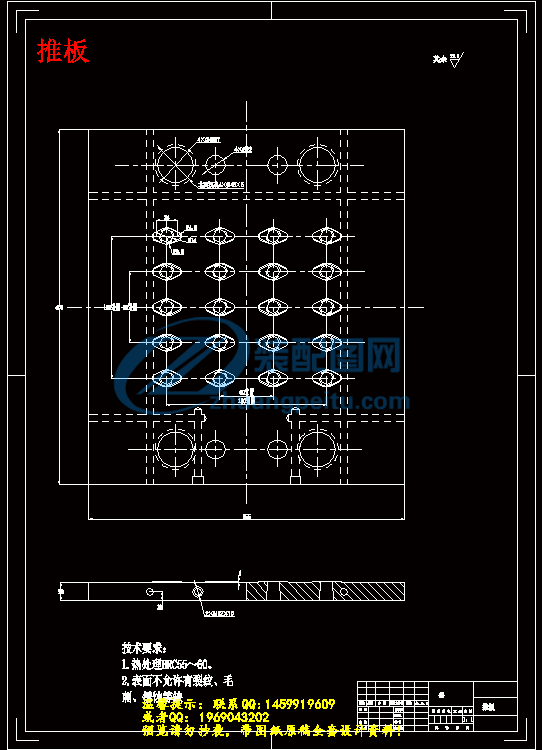

推板.dwg

文件清单.txt

点浇口.dwg

翻译.docx

装配图.dwg

说明书正文【切记务必使用07office来打开】.docx

调研报告.doc

摘 要

模具属于精密机械的产品,它主要机械零件和机构组成。如成形工作零件、导向零件、定位零件、支撑零件及送料机构、抽芯机构、推出机构等。模具与相应的成形设备(如冲床、塑料注射机、压铸机等)配套使用时,可直接改变金属或非金属材料的形状、尺寸、相对位置和性能,使之成形为合格的制件。

模具设计是模具制造的基础,合理正确的设计是正确制造模具的保证:模具制造技术的发展对提高模具质量、使用寿命、精度以及缩短制造模具周期具有重要的意义:模具的质量、使用寿命、制造精度及合格率在很大程度上取决于制造模具的材料及热处理工艺:模具成本直接关系到制件的成本以及模具生产企业的经济效益;模具工作零件的精度决定制件的精度;模具的寿命又与模具材料及热处理、模具结构以及所加工制作材料等诸多因素有关;模具的安装与使用直接关系到模具的使用性能及安全;而模具的标准化是模具设计与制造的基础,对大规模、专业化生产模具具有极重要的作用,模具标准化程度的高低是模具工业发展水平的标志。

本次设计注射器筒体的模具,设计中建模采用Cero PTC 4.0软件,AutoCAD为计算机辅助制图工具,是一款专业机械平面制图软件,具有很强的图像处理功能。

关键词:模具设计 注射器筒体 复合模

Abstract

Mold products are precision machinery, it mainly consists of mechanical parts and bodies,such as forming working parts, parts orientation, positioning parts, supporting parts, positioning components and feed mechanism, core-pulling mechanism, introduced institutions. Mold and the corresponding forming equipment (such as punching, plastic injection machine, die-casting machine, etc. ) supporting the use of, may directly alter the shape of metal or non-metallic materials, size, relative position and performance, shaping the work piece for qualified.

Mold manufacturing mold design is the basis for rational design of the right mold to ensure correct; mold manufacturing technology to improve the mold quality, service life, accuracy and shorten the manufacturing cycle is of great significance mold; mold quality, service life, manufacturing precision and the passing rate depends largely on the manufacture of mold materials and heat treatment; mold costs directly related to the work piece, the cost and economic efficiency of enterprises mold; determine the accuracy of the die components parts precision; dies life expectancy and the mold materials and heat treatment, mold structure and the production of materials processing, and many other factors; and mold die design and manufacturing and use of mold performance and safety; and mold die design and manufacturing standards are the basis of the same, large scale, specialized production mold is a very important role in standardization of the level of mold is a sign of mold level of industrial development.

The design of the syringe cylinder mold, the design of modeling using Cero PTC 4.0 software, AutoCAD for the computer-aided drawing tool, is a professional mechanical plane mapping software, has a strong image processing functions.

Key words: mold design syringe cylinder composite mold

目 录

第一章 设计任务书 1

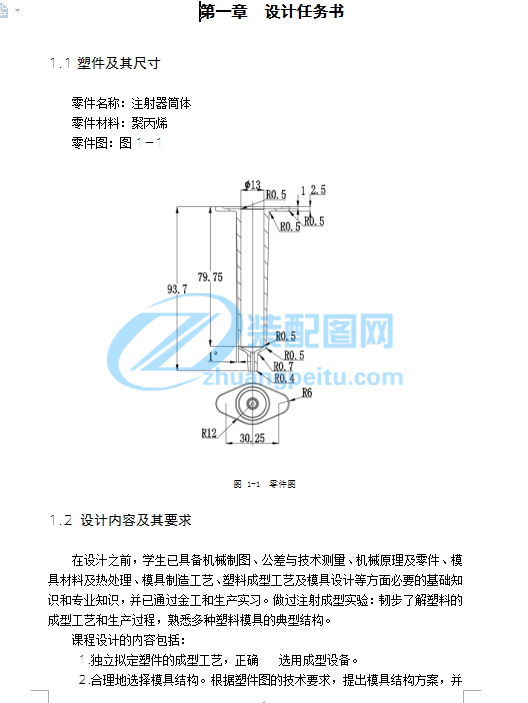

1.1塑件及其尺寸 1

1.2 设计内容及其要求 1

第二章 塑件成型工艺分析 3

2.1塑件的分析 3

2.2PP聚丙烯的性能分析 3

第三章 拟定模具的结构形式 5

3.1分型面位置确定 5

3.2型腔数量和排列方式的确定 5

3.3注射机的型号确定 6

第四章 浇注系统的设计 8

4.1主流道的设计 8

4.2分流到的设计 9

4.3浇口的设计 12

4.4校核主流道的剪切速率 13

第五章 模具零件的结构设计及计算 14

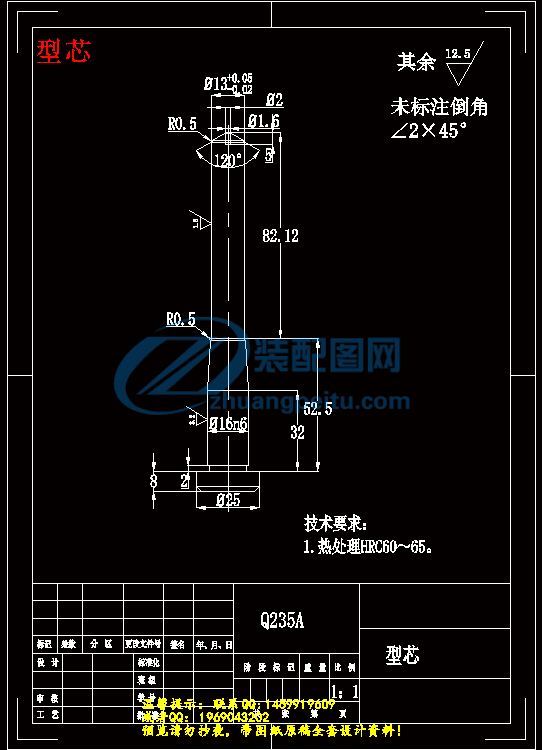

5.1成型零件的结构设计 14

5.2成型零件钢材的选用 15

5.3成型零件工作尺寸的计算 15

5.4模架的确定 16

5.5排气槽的设计 17

5.7冷却系统的设计 18

5.8导向与定位结构 20

5.9总装图和零件图的绘制 20

谢辞 21

参考文献 22