六孔警灯注塑模设计【一模一腔优秀课程毕业设计含proe三维28张CAD图纸+带外文翻译】

六孔警灯注塑模设计【一模一腔含28张CAD图纸及proe三维】

摘 要

塑料制品具有原料来源丰富,价格低廉,性能优良等特点。它在电脑、手机、汽车、电机、电器、仪器仪表、家电和通讯产品制造中具有不可替代的作用,应用极其广泛。注射成 形是成形热塑件的主要方法,因此应用范围很广。

本次的毕业设计是六孔警灯的注塑模具的设计。 依据产品的数量和塑料的工艺性能确定塑件采用注射成形法生产,模具的型腔采用单腔平衡布置。本次的设计中不仅参考了大量纸质文献,而且在互联网上查阅资料,设计过程比较完整。

关键词: 六孔警灯 ,注塑模具,单腔

Abstract

Plastic products are rich in raw materials, low price, good performance and so on. It plays an irreplaceable role in the manufacture of computers, mobile phones, automobiles, motors, electrical appliances, instruments and meters, household appliances and communication products, and is widely used. Injection molding is the main method of forming thermoplastic parts, so it has a wide range of applications.

This graduation design is the design of the injection mold for the six lights. According to the quantity of the product and the technological performance of the plastic, the plastic parts are produced by injection molding, and the mold cavity is balanced with a single cavity. This design not only refers to a large number of paper documents, but also searches data on the Internet, and the design process is more complete.

Key words: six lights, plastic injection mold, single cavity

目 录

第一章 塑件建模 ·························· 1

第二章 塑件成型工艺分析 ······················ 2

2. 1 塑件的分析 ·························· 2

2. 1. 1 外形尺寸 ························· 2

2. 1. 2 精度等级 ························· 3

2. 1. 3 脱模斜度 ························· 4

2. 2 材料(PC)的性能分析 ····················· 4

2. 2. 1 使用性能 ························· 4

2. 2. 2 成型性能 ························· 4

2. 2. 3 PC 材料详细参数 ······················ 5

2. 3 PC 的主要加工过程参数与注意事项 ··············· 5

2. 3. 1 原料的干燥 ························ 5

2. 3. 2 注射工艺 ························· 5

2. 3. 3 注意事项 ························· 6

第三章 拟定模具的结构形式 ····················· 7

3. 1 分型面位置的确定 ······················· 7

3. 2 型腔数量和排列方式的确定 ··················· 7

3. 2. 1 型腔数量的确定 ······················ 7

3. 2. 2 型腔排列形式的确定 ···················· 7

3. 2. 3 模具结构形式的确定 ···················· 7

3. 3 注射机型号的确定 ······················· 7

3. 3. 1 注射量的计算 ······················· 7

3. 3. 2 浇注系统凝料体积的初步估算 ················ 7

3. 3. 3 选择注射机 ························ 7

3. 4 注射机的相关参数的校核 ···················· 8

3. 4. 1 注射压力校核 ······················· 8

3. 4. 2 锁模力校核 ························ 8

第四章 浇注系统设计 ························ 9

4. 1 主流道设计 ·························· 9

4. 1. 1 主流道尺寸 ························ 9

4. 1. 2 主流道的凝料体积 ····················· 9

4. 1. 3 主流道的当量半径 ····················· 9

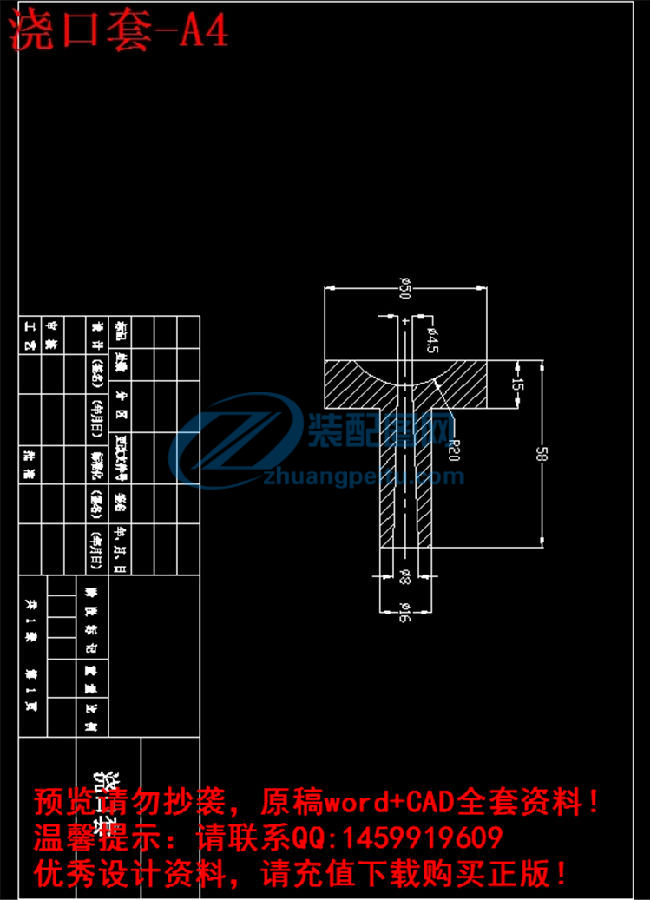

4. 1. 4 主流道的浇口套形式 ···················· 9

4. 2 分流道设计 ·························· 10

4. 3 浇口的设计 ·························· 10

4. 4 校核主流道的剪切速率 ····················· 11

4. 5 冷料穴的设计 ························· 11

第五章 成型零件设计计算 ····················· 12

5. 1 成型零件的结构设计 ······················ 12

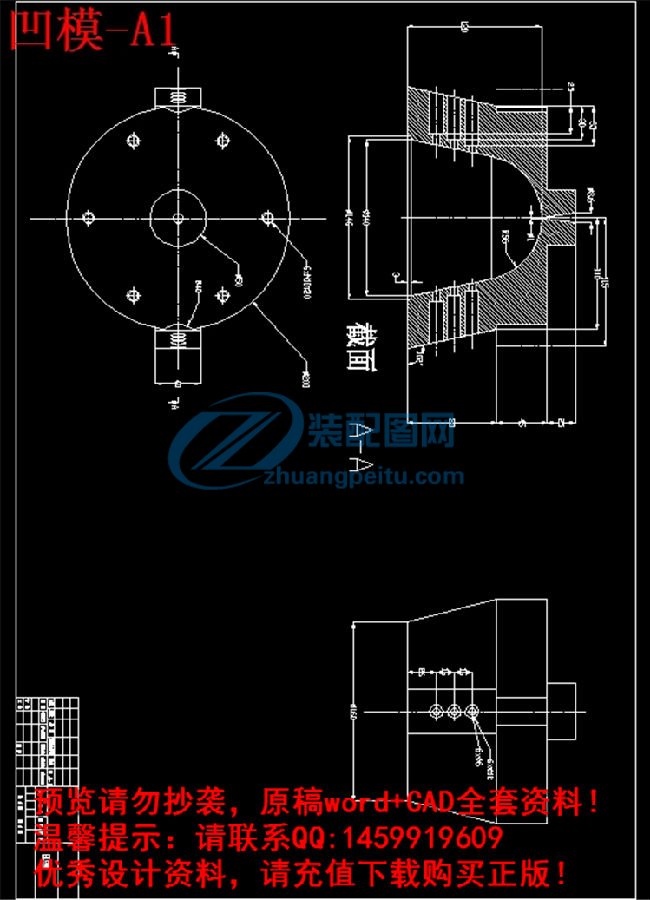

5. 1. 1 凹模的结构设计 ······················ 12

5. 1. 2 凸模的结构设计 ······················ 12

5. 2 成型零件钢材的选用 ······················ 12

5. 3 成型零件工作尺寸的计算 ···················· 12

5. 3. 1 凹模径向尺寸的计算 ···················· 12

5. 3. 2 凹模深度尺寸的计算 ···················· 12

5. 3. 3 型芯径向尺寸的计算 ···················· 13

5. 3. 4 型芯高度尺寸的计算 ···················· 13

5. 3. 5 侧抽芯中心距的计算 ···················· 13

第六章 模架选型 ························· 14

6. 1 模板尺寸确定 ························· 14

6. 2 模架各尺寸的校核 ······················· 14

第七章 排气槽设计 ························ 15

第八章 脱模推出机构设计 ····················· 16

8. 1 推出方式 ··························· 16

8. 2 脱模力计算 ·························· 16

8. 3 校核推出机构作用在塑件上的单位压应力 ············· 16

8. 3. 1 推出面积 ························· 16

8. 3. 2 推出应力 ························· 16

第九章 冷却系统设计 ······················· 17

9. 1 冷却介质 ··························· 17

9. 2 冷却系统的简单计算 ······················ 17

9. 2. 1 单位时间内注入模具的塑料熔体的总质量 W ·········· 17

9. 2. 2 确定单位质量的塑件在凝固时放出的热量 Qs ·········· 17

9. 2. 3 计算冷却水的体积流量 qv ·················· 17

9. 2. 4 确定冷却水路的直径 d ··················· 17

9. 2. 5 冷却水在管内的流速 v ··················· 17

9. 2. 6 求冷却管壁与水交界面的膜传热系数 h ············ 17

9. 2. 7 计算冷却水通道的导热总面积 A ··············· 18

9. 2. 8 计算模具所需冷却水管的总长度 L ·············· 18

9. 2. 9 冷却水路的根数 x ····················· 18

9. 3 冷却水道的设置 ························ 18

第十章 导向与定位结构设计 ···················· 19

第十一章 总装图和零件图的绘制 ·················· 20

谢 辞 ···························· 21

参考文献 ···························· 22

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

3D.stp

proe模型

主推板-A2.dwg

侧抽芯-A4.dwg

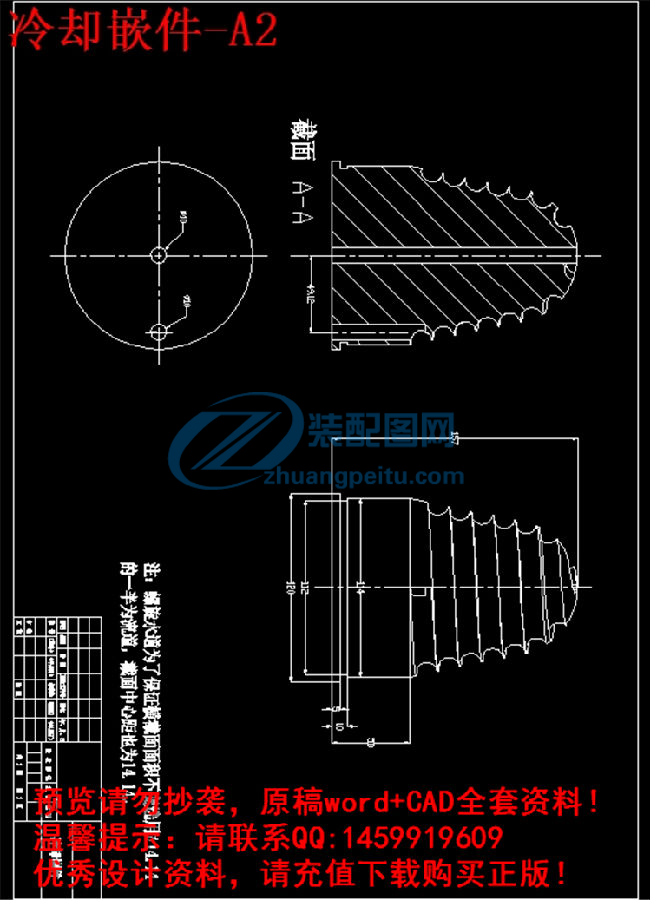

冷却嵌件-A2.dwg

凹模-A1.dwg

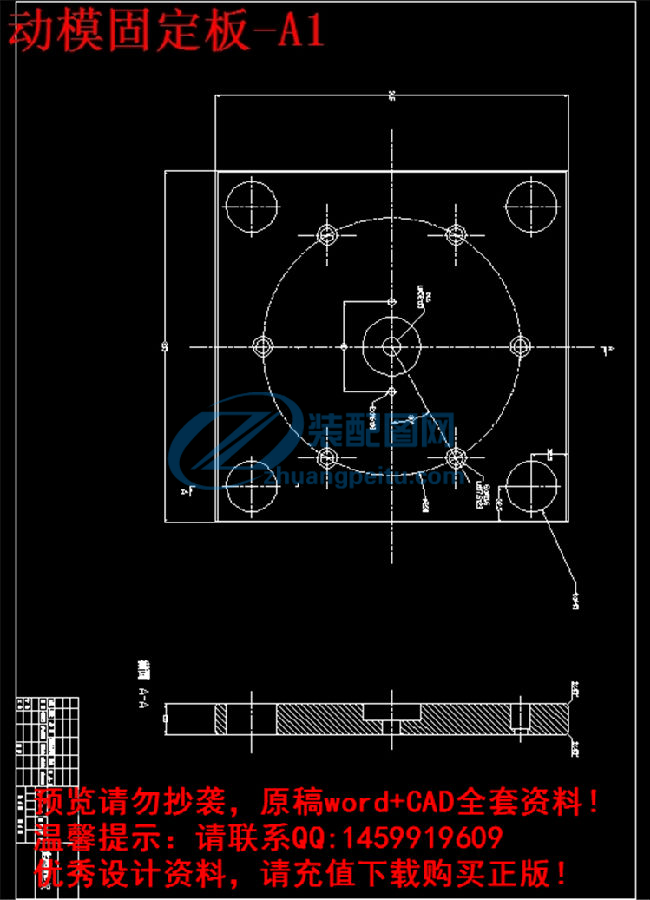

动模固定板-A1.dwg

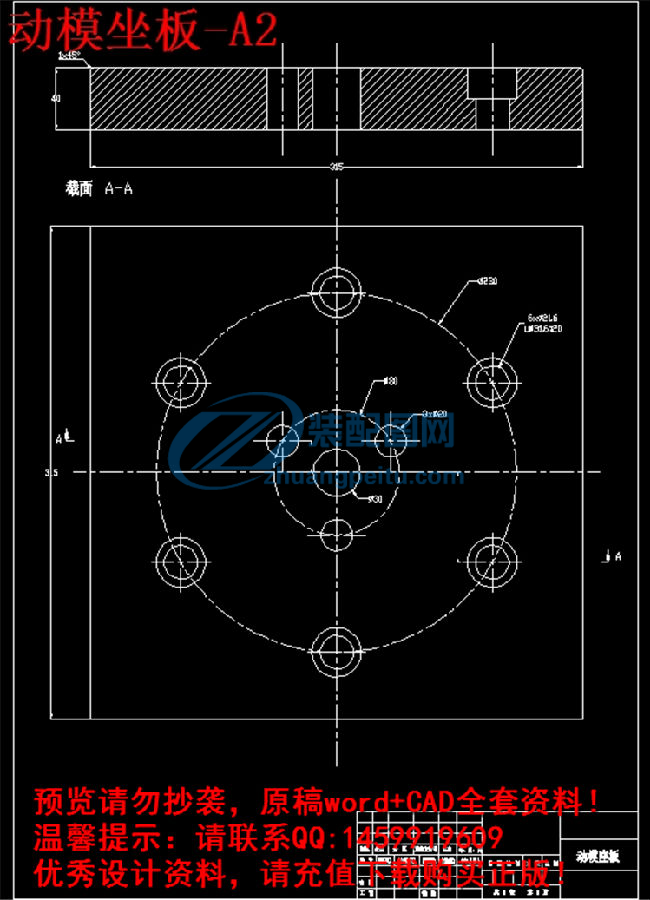

动模坐板-A2.dwg

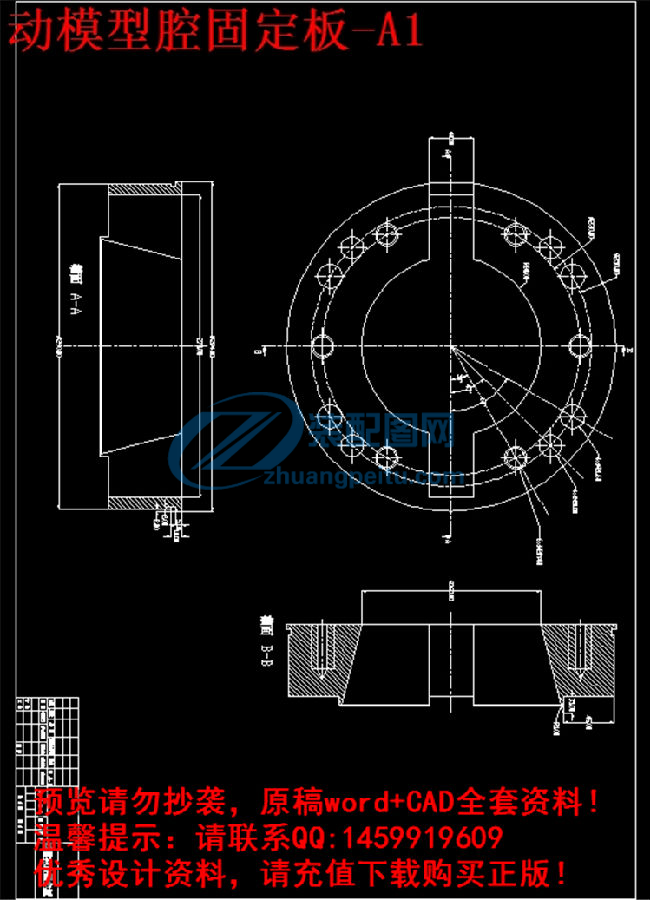

动模型腔固定板-A1.dwg

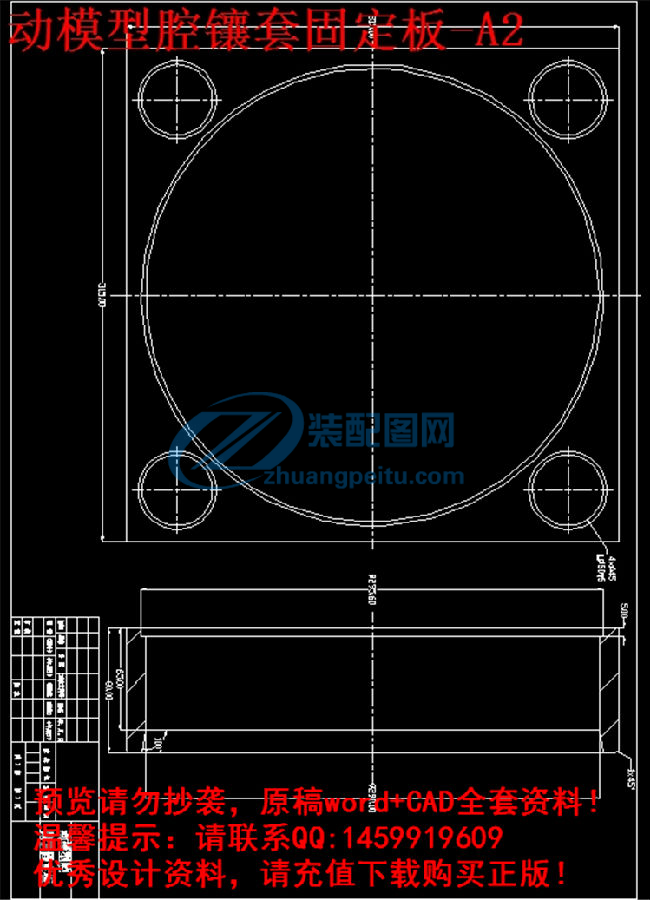

动模型腔镶套固定板-A2.dwg

型芯-A3.dwg

垫板-A1.dwg

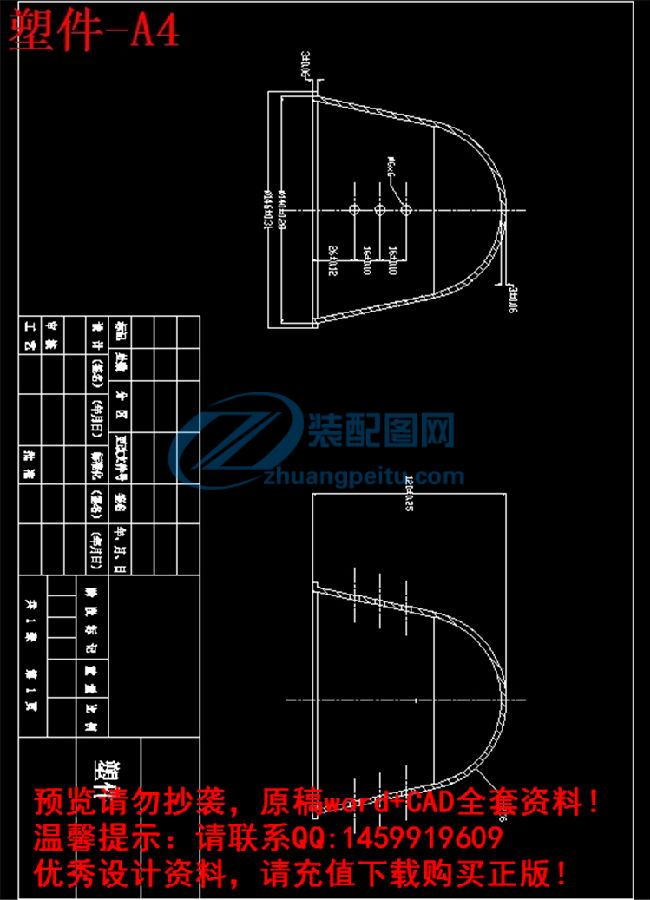

塑件-A4.dwg

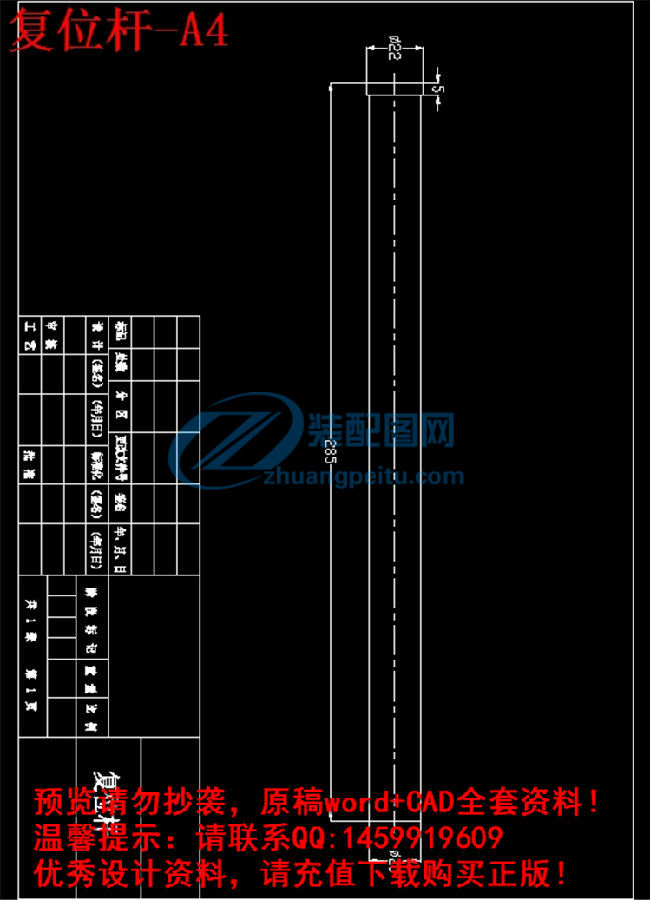

复位杆-A4.dwg

定位圈-A4.dwg

定模镶套-A3.dwg

定距拉杆-A4.dwg

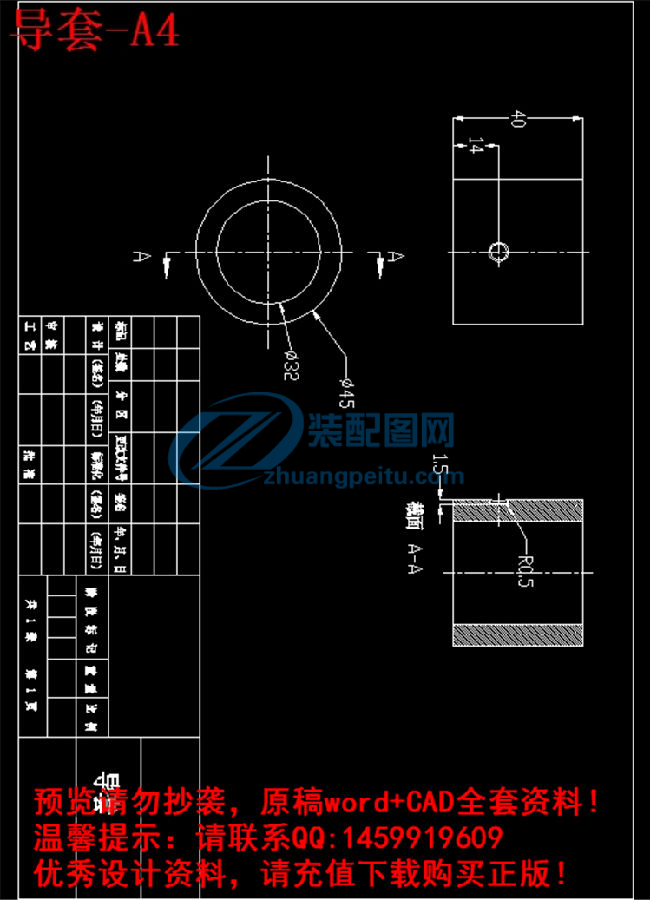

导套-A4.dwg

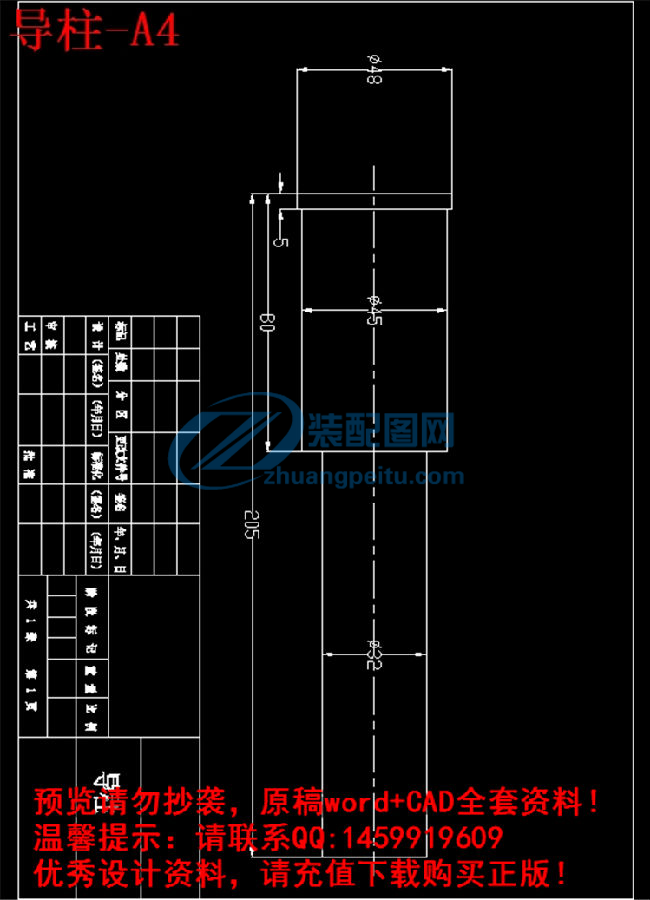

导柱-A4.dwg

小支撑柱-A4.dwg

打印

打印.zip

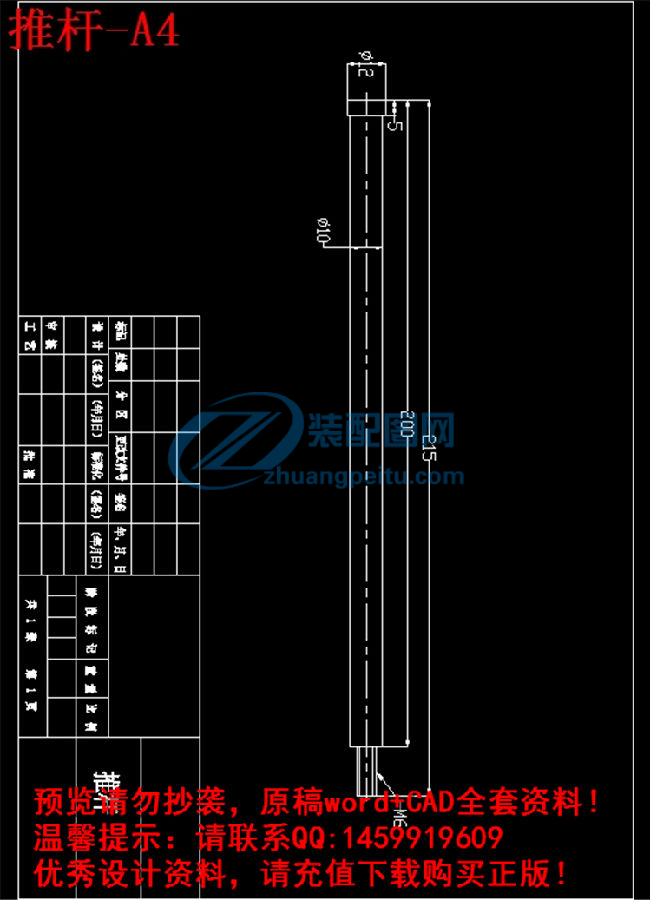

推杆-A4.dwg

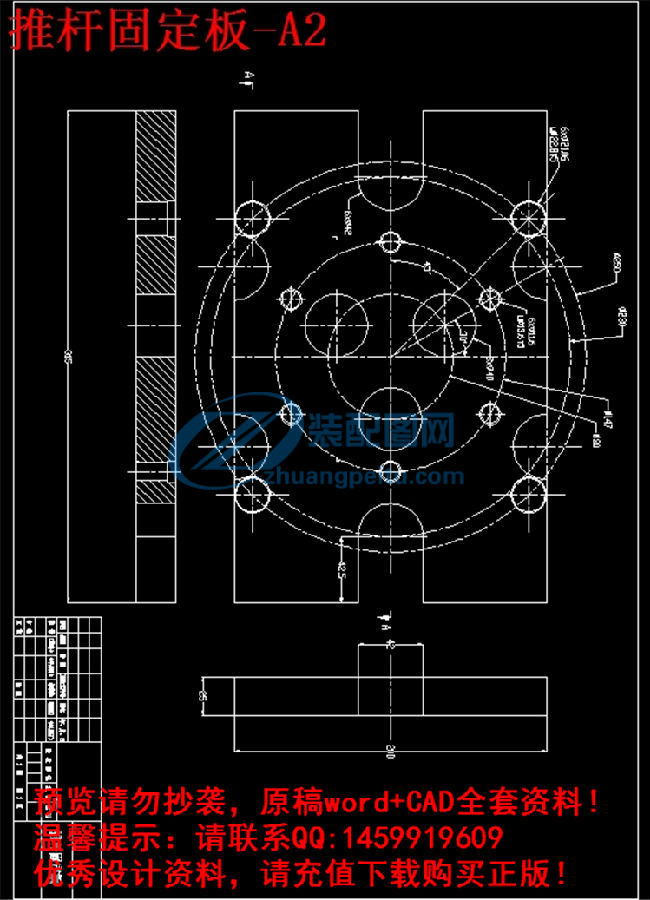

推杆固定板-A2.dwg

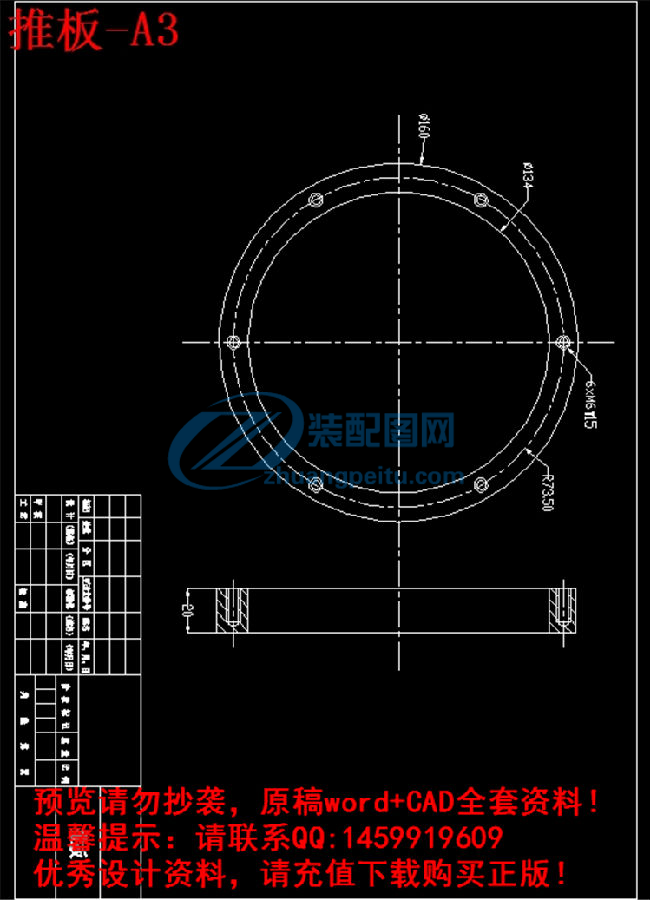

推板-A3.dwg

支撑板-A2.dwg

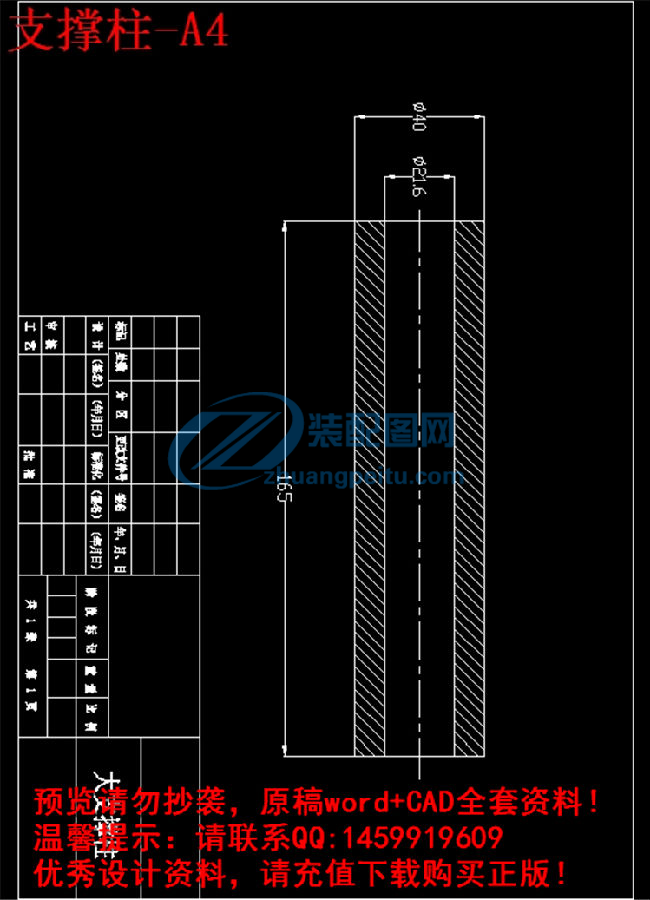

支撑柱-A4.dwg

文件清单.txt

浇口套-A4.dwg

盖板-A2.dwg

装配图-A0.dwg

设计说明书.doc

说明书 .pdf

锁紧嵌块-A4.dwg

锁紧嵌块固定板-A2.dwg