C616卧式车床八工位数控回转刀架设计【八工位卧式电动控制刀架+优秀课程毕业设计+含6张CAD图纸+带文献综述+36页加正文1.61万字】-jxsj11

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

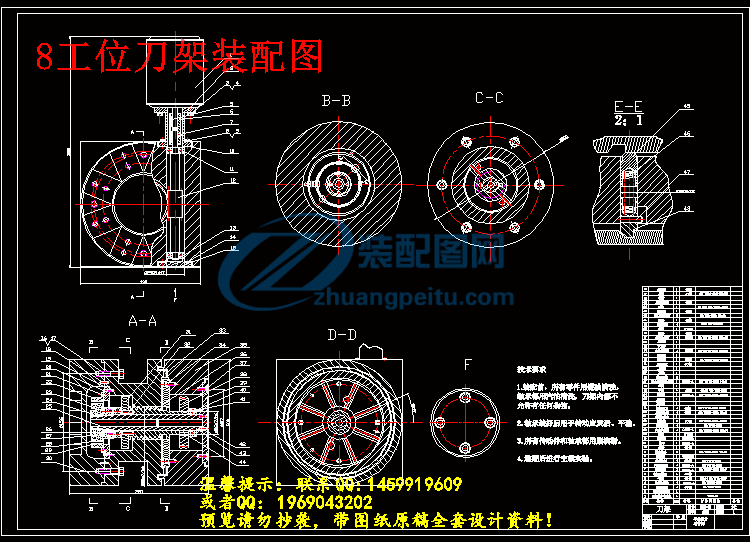

8工位刀架装配图.dwg

刀盘.dwg

图纸副本.zip

文件清单.txt

文献综述.doc

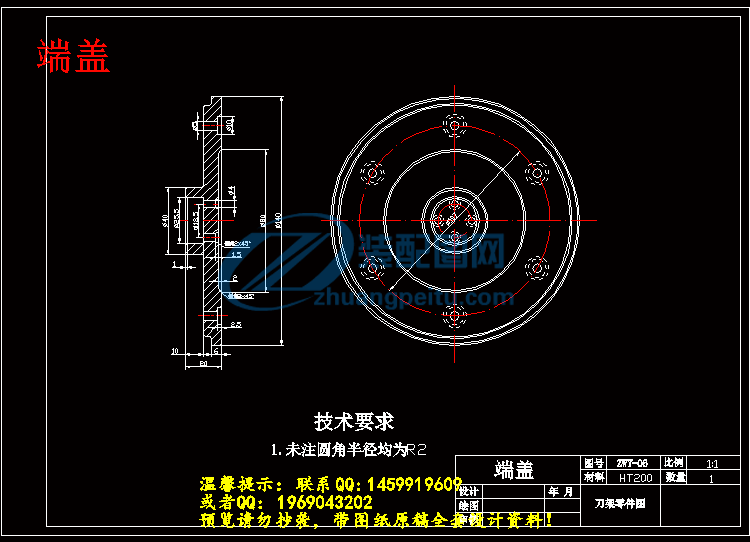

端盖.dwg

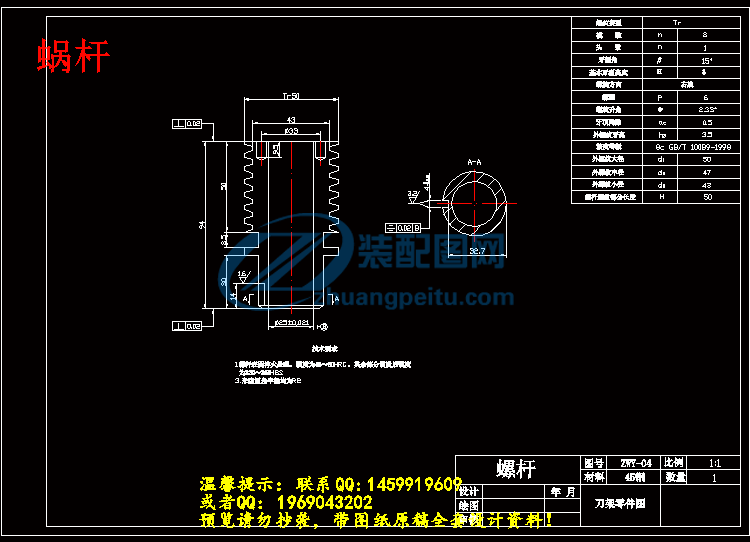

蜗杆.dwg

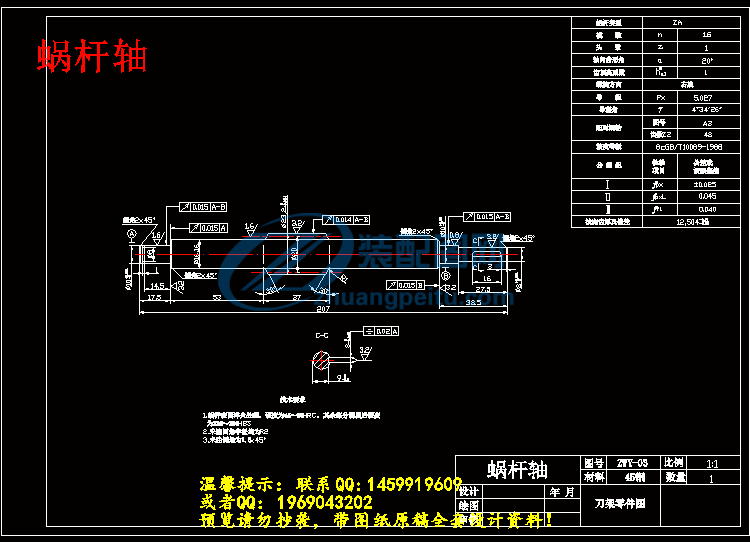

蜗杆轴.dwg

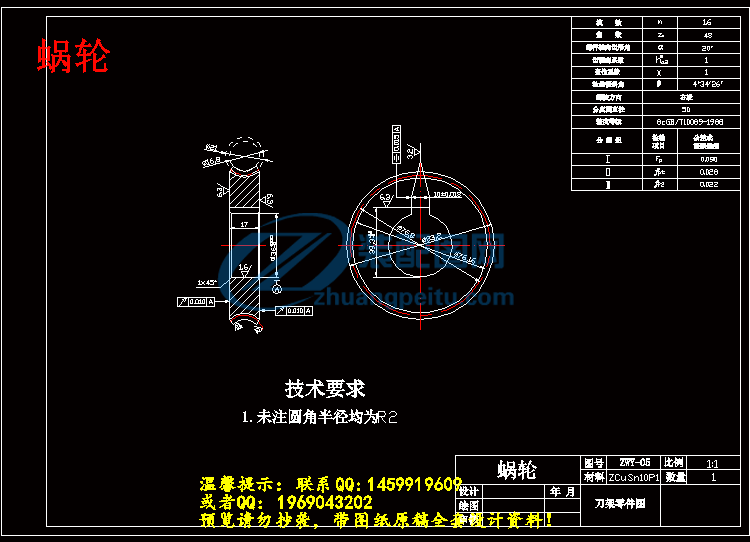

蜗轮.dwg

说明书正文.doc

零件总汇图纸.dwg

摘 要

数控加工的加工精度高,生产率高,能减轻操作者劳动强度、改善劳动条件,有利于生产管理的现代化以及经济效益的提高,它的发展和运用,影响着制造业水平高低,实现生产过程的数控化,已经成为当今制造业的发展方向,所以非常值得我们去研究。

本设计通过对八工位卧式电动控制刀架的工作原理的分析,确定了多种方案,综合考虑各种方案的优缺点、性价比后,采用电动回转刀架。其刀架机构的主要部件包括减速传动机构、刀架的抬起机构、锁紧与转位精定位机构等,控制系统软件包括控制系统的选择,控制系统软硬件的设计,收发信电路的设计等,设计中所采用螺杆抬起机构、端齿盘定位机构和单片机控制系统都计较经济实用,适合我们我国现阶段数控机床的发展需要。

关键词 八工位,电动刀架,自动化,8051单片机

ABSTRACT

The numerical control processing's working accuracy is high, the productivity is high, can reduce the operator labor intensity, the improvement work condition, is advantageous in production management modernization as well as the economic efficiency enhancement, its development and the utilization, are affecting the manufacturing industry horizontal height, realizes the production process numerical control, already became now the manufacturing industry development direction, therefore is worth us studying. this design through to eight location horizontal type electric control tool rest's principle of work's analysis, had determined many kinds of plans, after overall evaluation each kind of plan good and bad points, performance-to-price ratio, uses the electrically operated turret saddle. Its tool rest organization's major component including the reduction gear organization, the tool rest lifts the organization, to lock and to index the fine detent mechanism and so on, the control system software including control system's choice, the control system software and hardware's design, receives transmitting circuit's design and so on, in the design uses the screw rod to lift the organization, the end tooth plate detent mechanism and the monolithic integrated circuit control system haggles over the economy to be practical, suits our our country present stage numerically-controlled machine tool's development need. key word eight locations, electrically operated tool rest, automation, 89C51 monolithic integrated circuit.

Keywords eight locations, electrically operated tool rest, automation, 8051 monolithic integrated circuit.

目 录

摘要 I

ABSTRACT II

1 绪论 1

1.1 引言 1

1.2 国内外研究现状 1

1.3 存在的问题 2

1.4 解决的方法 3

2 方案设计 4

2.1 自动刀架的基本要求和类型 4

2.1.1自动刀架的基本要求 4

2.1.2自动刀架的类型 4

2.2 方案的拟定和确定 5

3 总体结构设计 7

3.1 减速传动机构方案设计 7

3.2 刀架抬起机构设计 8

3.3 上刀体锁紧与精定位机构设计 8

4 主要部件的设计计算 11

4.1 减速传动机构的设计计算 11

4.1.1蜗杆的选型 11

4.1.2蜗杆副的材料选择 11

4.1.3按齿面接触疲劳强度进行设计 11

4.1.4蜗杆和蜗轮的主要参数与几何尺寸 14

4.1.5校核蜗轮齿根弯曲疲劳强度 15

4.2 螺杆的设计计算 16

4.2.1螺距的确定 16

4.2.2其他参数的确定 16

4.2.3自锁性能校核 16

4.3 端齿盘设计 17

4.3.1 端齿盘的特点 17

4.3.2 端齿盘主要参数的设计计算 18

5 电气控制部分设计 21

5.1 控制系统的选择 21

5.2 控制方式的选择 22

5.3 硬件电路设计 22

5.3.1收信电路设计 22

5.3.2发信电路设计 23

5.4 控制软件设计 25

结论 30

参考文献 31

致谢 32