四柱万能液压机总体及液压系统设计【公称压力为2500kN优秀课程毕业设计含2张CAD图纸+带开题报告】

四柱万能液压机总体及液压系统设计【公称压力为2500kN】

摘要

进入19世纪以来,随着制造业的飞速发展,对机械加工设备的要求也越来越高,人们迫切需要一种通用性强,加工范围广,工作负载大的加工设备。尽管早在17世纪中期帕斯卡就发现了利用液体能产生很大力量的可能性,但直到19世纪,液压技术才得到人们的广泛重视。为了应对军事、航空工业等领域的需求,德国、英国、苏联等国家先后制造了一批公称压力达到上万吨的模锻液压机。这个时候液压成型机械得到了充分的发展并具有了成熟的技术。液压机广泛应用于金属薄板的冲压拉深成形;金属机械零件的压力成形;粉末制品行业;非金属材料的压制成形;木制品的热压成形等领域。液压机极强的通用性奠定了它在工业生产领域的重要地位,成为国民生产中一枚关键的“棋子”。

本文对液压成型机械做了简单的回顾和总结,并具体设计了一台公称压力为2500kN的通用液压机,重点在于液压系统设计方面,详细拟定了液压系统压力、方向控制等回路,绘制了液压系统图,并选择了各液压元件的具体型号等。

为了满足工业生产的需要,促进国民经济发展,我国必须加大液压成型机械的研发和设计制造,争取早日达到国际先进水平,打破西方发达国家对液压关键元件的技术垄断。

关键词:液压机;液压缸;液压系统;横梁;液压阀

Abstract

In the 19 century, with the rapid development of manufacturing, machinery processing equipment requirements are also getting higher and higher, People urgently need a high universality, processing a wide range of the work load of processing equipment. Although as early as the mid-17th century Pascal discovered the use of liquid can produce the possibility of great power, It was not until the 19th century, hydraulic technology to receive widespread attention. In response to the military, aviation industry and other areas of demand, Germany, Britain, the Soviet Union and other countries has created a number of Nominal pressure reached 10,000 tons of forging hydraulic press. This time forming hydraulic machinery were fully developed and is a mature technology. Hydraulic press widely used in the sheet metal stamping drawing, metal machine parts pressure forming; powder products industry; non-metallic materials to suppress forming; wood products in areas such as the hot press forming. Hydraulic highly versatile for its industrial production in the area of the important status and become an indispensable national product of a "pawn."

In this paper, hydraulic molding machine to do a simple review and sum up, and specifically designed for a Nominal pressure of 2500 kN Hydraulic presses, focused on the design of the hydraulic system, the elaboration of the hydraulic pressure system, the direction of control loop, rendering The hydraulic system map, and select the various hydraulic components such as the specific models.

In order to meet the needs of industrial production, promote economic development, China must increase the hydraulic molding machinery design and manufacture of the research and development and to strive for an early reached the international advanced level, breaking the Western developed countries on key components of the hydraulic technology monopoly.

Key words: hydraulic machine; hydraulic cylinder; hydraulic system; beams; hydraulic valve

目录

摘要 1

Abstract 2

目录 3

0前言 5

1绪论 6

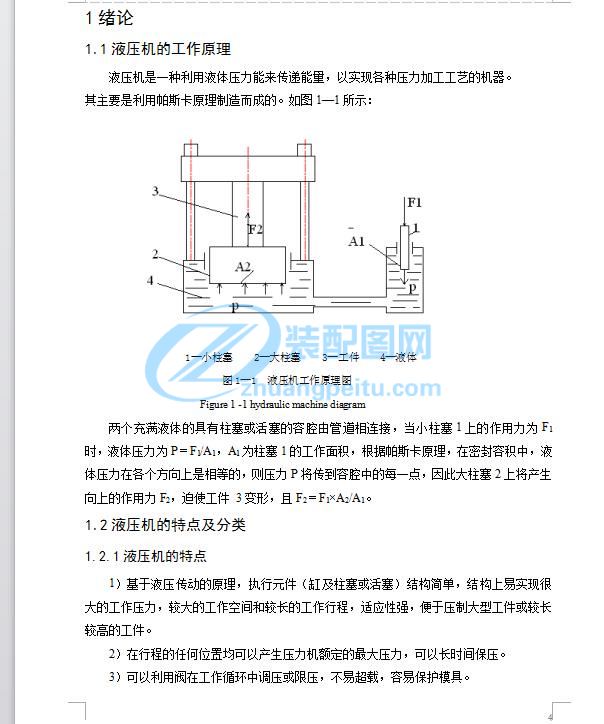

1.1液压机的工作原理 6

1.2液压机的特点及分类 6

1.2.1液压机的特点 6

1.2.2液压机的分类 7

1.3液压机的选择 7

1.4液压机发展历程 7

1.5国内液压机技术发展情况 8

2液压机的本体结构及设计 9

2.1四柱万能液压机的结构及工作特点 9

2.1.1结构 9

2.1.2工作特点 9

2.2四柱万能液压机的基本参数 9

2.3液压缸设计 11

2.3.1液压缸的结构 11

2.3.2主缸设计 12

2.3.3 顶出缸设计 18

2.4四柱式组合机架设计 20

2.4.1立柱 21

2.4.2横梁 24

3液压机的液压系统设计 27

3.1明确液压系统的技术要求 27

3.2液压系统的功能设计 27

3.2.1执行器的配置 27

3.2.2动力分析和运动分析 28

3.3液压系统主要参数的确定 29

3.3.1液压缸有效工作面积A 29

3.3.2液压缸的最大流量Qmax 30

3.4拟定液压系统原理图 30

3.4.1执行元件类型的选择 30

3.4.2方向控制回路 30

3.4.2.换向回路 30

3.4.3速度控制回路 31

3.4.4压力控制回路 33

3.4.5液压油源回路 36

3.4.6液压系统的合成 36

3.5液压元件的计算和选择 39

3.5.1 液压泵的选择 39

3.5.2电机的选择 41

3.5.3液压阀的选择 41

3.5.4油管的选择 42

3.5.5油箱 44

4液压机的振动及减振措施 47

4.1液压机的振动 47

4.2液压机的减振措施 47

3)产生液压冲击时的减振措施 48

5结论 49

致谢 50

参考文献 51

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

内封.doc

四柱万能液压机总体及液压系统设计【公称压力为2500kN】说明书正文.doc

实习报告.doc

开题报告.doc

摘要.doc

文件清单.txt

液压原理图-A2.dwg

液压机总图-A0.dwg