堵头注塑模具设计【一模四腔优秀课程毕业设计含proe三维26张CAD图纸+带外文翻译】-zsmj09

堵头注塑模具设计【一模四腔含26张CAD图纸及proe三维】

摘 要

从19世纪开始,塑料就开始发展了起来,从合成树脂到现在各种各样的化合物,可谓是日益完善,而模具也是从这时候发展起来的。塑料模具的分类很多,按照塑料制件的不同可分为:注射模、压缩模、压注模、挤出模、气动成型模等。注塑模具又称注塑成型,是热塑性塑料制品生产的一种重要的方法。除少数塑料制品外,几乎所有的热塑性塑料都可以用注射成型方法生产塑料制品。现如今模具已经成为了发展中不可或缺的产物,对未来的发展也有这重大的贡献。

本文主要介绍堵头注塑模具的设计方法。首先通过对堵头工艺特点,包括材料性能、结构工艺和成型特性等进行分析而进行设计。在设计该模具的同时,学习模具知识和设计方法,通过旋转脱螺纹机构的设计,融汇了课程中的基础知识到其中。同时引用了CAD、Pro/E等技术,建立修改二维三维图纸。而在应用软件的同时,也发现自己的不足并改进,从而提高自己对零件的了解和软件的熟练操作,从而达到设计目的。

关键词:注塑模 旋转脱螺纹 堵头 三维图

ABSTRACT

From the 19th century, the plastic began to develop, from synthetic resin to now a variety of compounds, can be described as increasingly perfect, and the mold is also developed from this time. Plastic mold a lot of classification, according to the different plastic parts can be divided into: injection mold, compression mold, injection mold, extrusion die, pneumatic molding die. Injection molding mold, also known as injection molding, is an important method of production of thermoplastic products. In addition to a small number of plastic products, almost all of the thermoplastic can be used to produce plastic injection molding method. Now the mold has become an indispensable product of development, the future development also has this significant contribution.

This paper mainly introduces the design method of plug injection mold. First of all, through the plug process characteristics, including material properties, structural processes and molding characteristics of the analysis and design. In the design of the mold at the same time, learning mold knowledge and design methods, through the rotation off the screw body design, integration of the basic knowledge of the course to which. At the same time cited the CAD, Pro / E and other technologies, the establishment of modified two-dimensional three-dimensional drawings. And in the application software at the same time, also found their own deficiencies and improvements, so as to improve their understanding of the parts and software proficiency in operation, so as to achieve the purpose of the design.

Key words: injection mold Rotate off the thread Plug Three-dimensional map

目 录

第一章 塑件的设计 1

1.1塑件材料 1

1.1.1材料的性能分析 1

1.1.2主要性能指标 1

1.1.3尼龙1010的注射成型过程及工艺参数 2

1.2塑件的结构分析 2

1.2.1塑件的二维图 2

1.2.2塑件的三维图 2

第二章 模具的结构形式 3

2.1型腔数量和排列方式的确定 3

2.2注射机型号的确定 4

第三章 浇注系统的设计 5

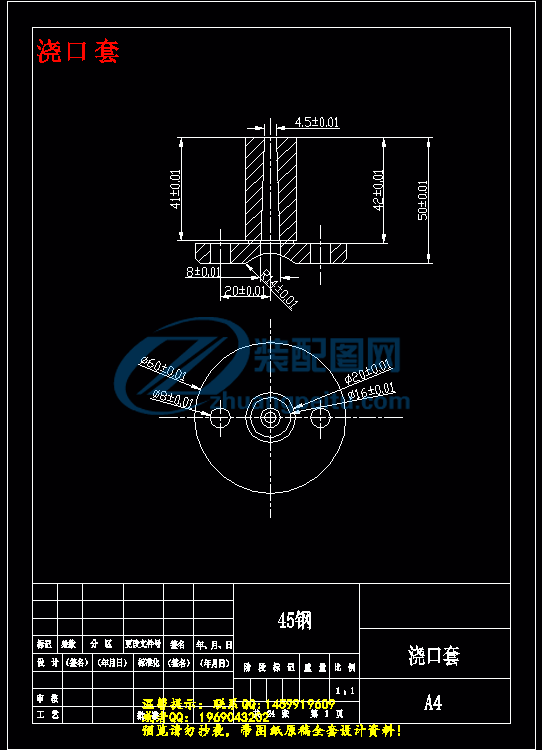

3.1浇注系统的设计 5

3.1.1主流道设计 5

3.1.2分流到的设计 6

3.2浇口的设计 7

3.3校核浇口剪切速率 7

3.4校核主流道的剪切速率 7

3.5脱模机构 8

第四章 成型零件的设计计算 9

4.1成型零件钢才的选用 9

4.2成型零件工作尺寸的计算 10

第五章 模架选型 11

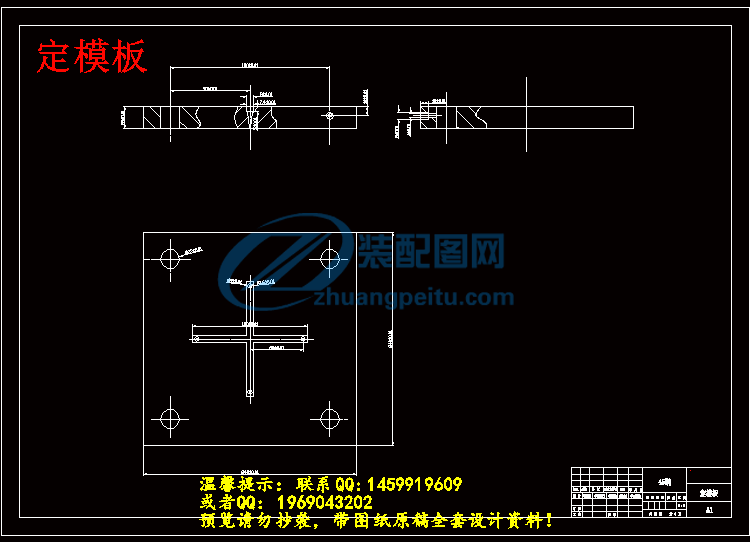

5.1模板尺寸确定 11

5.2模架尺寸的校核 12

第六章 其他零部件的设计 12

6.1排气槽设计 12

6.2冷却系统的设计 12

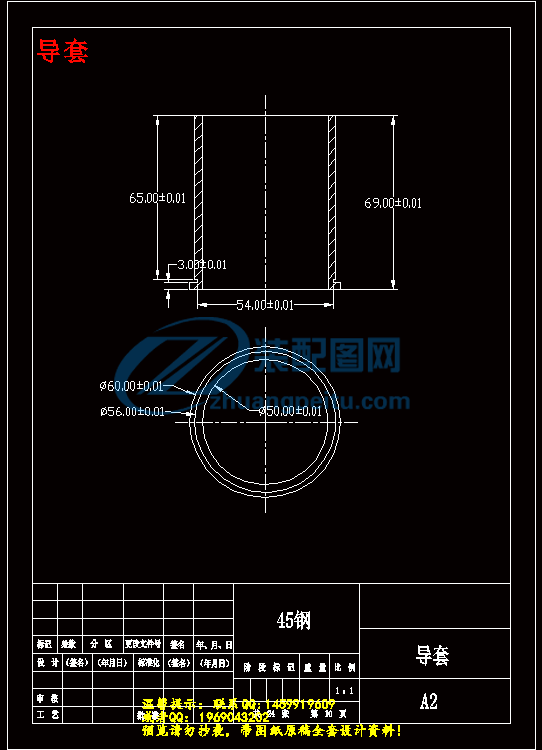

6.3模具导向机构的设计 13

第七章 结论 14

7.1结论 14

7.2研究难点 14

7.3研究不足 14

谢 辞 15

参考文献 16

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

lingjian001.stp

proe三维

zp01.stp

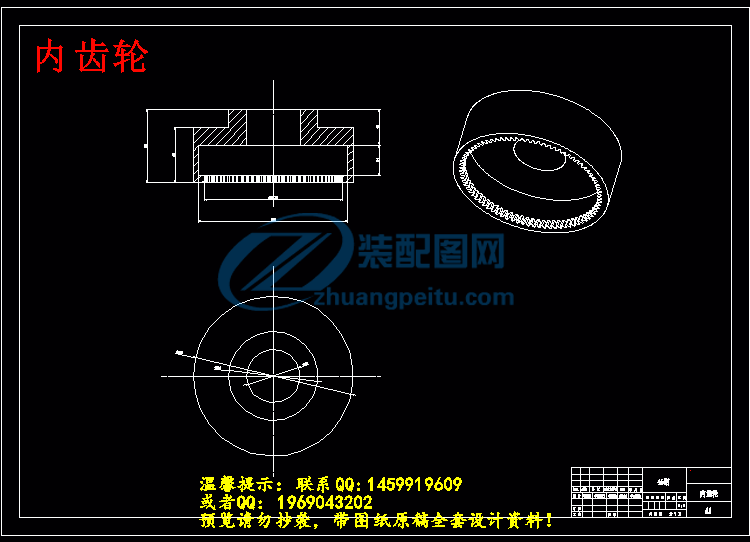

内齿轮.dwg

动模垫板.dwg

动模导套.dwg

动模座板.dwg

动模板.dwg

图纸副本

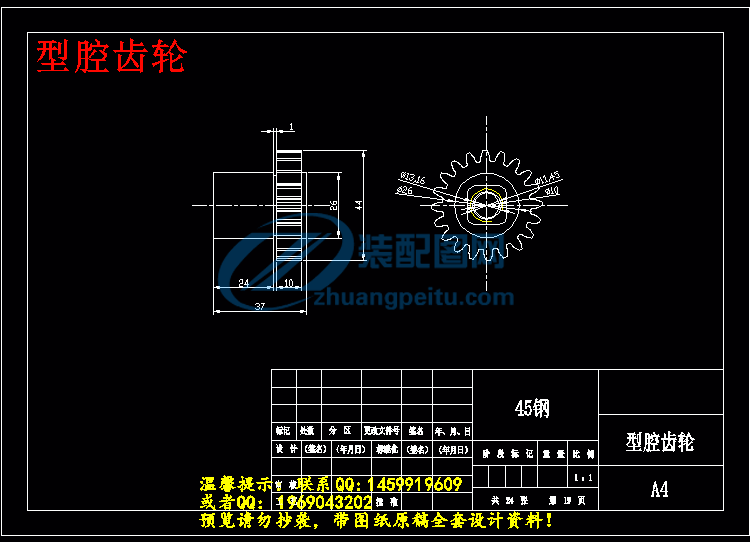

型腔齿轮.dwg

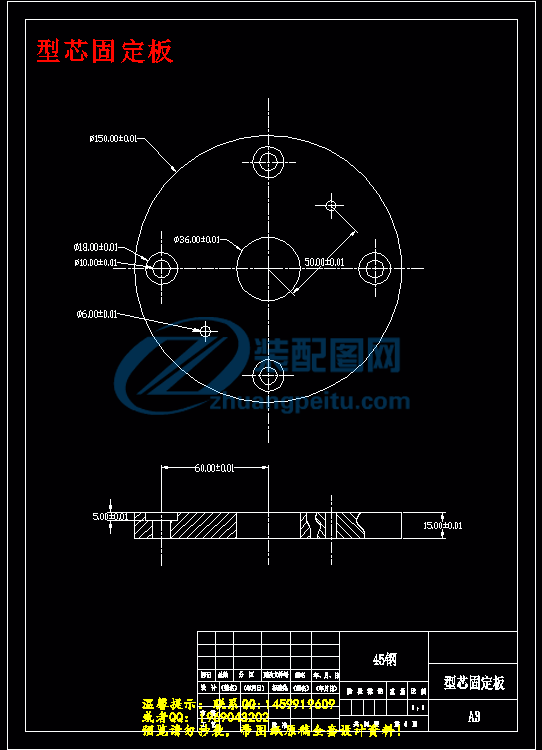

型芯固定板.dwg

堵头塑件图.dwg

堵头注塑模具设计【一模四腔含说明书正文】.wps

定模导套.dwg

定模板.dwg

导套.dwg

导杆拉杆.dwg

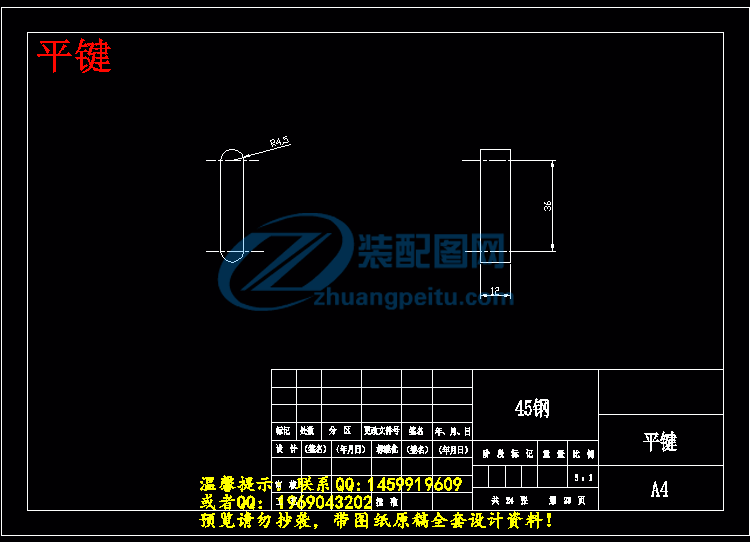

平键.dwg

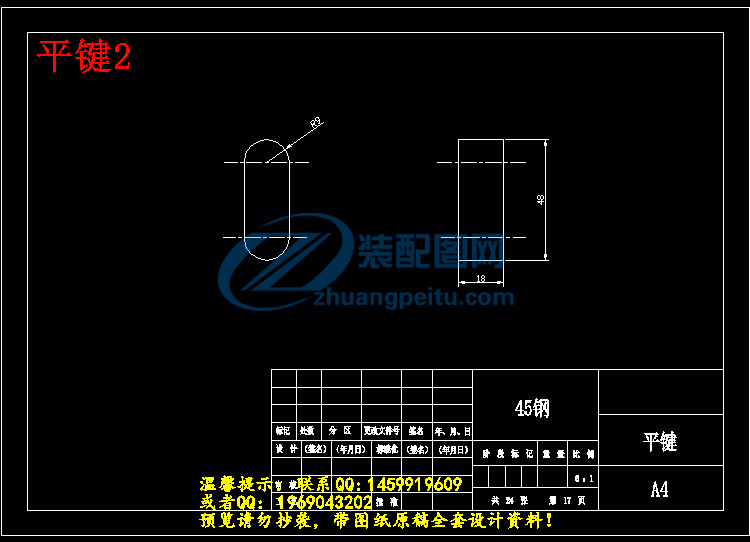

平键2.dwg

平键3.dwg

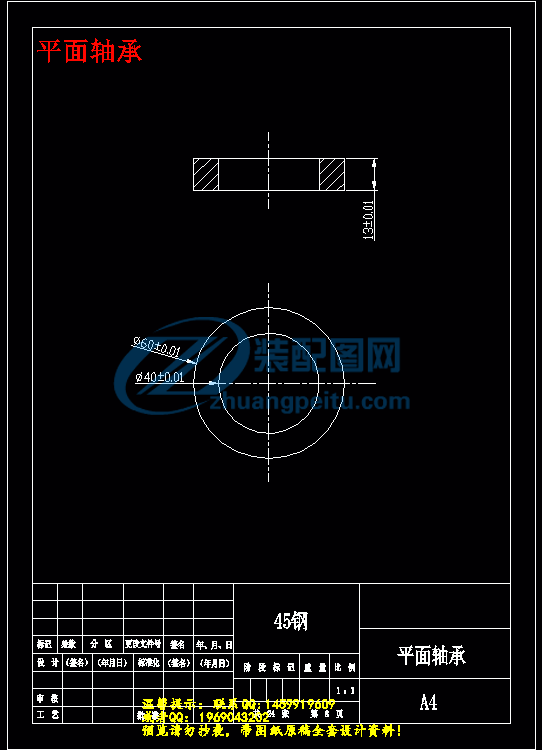

平面轴承.dwg

挡圈.dwg

文件清单.txt

止转螺钉.dwg

活动块.dwg

浇口套.dwg

浇口板.dwg

滚珠丝杆.dwg

滚珠螺母.dwg

螺钉.dwg

装配图.dwg

顶杆.dwg